Insulation Color Changing Systems

Automatic insulation color change systems for full extrusion line speed changeovers are available.

Depending on product and requirement, one can choose from about 2 dozen different systems.

The systems are set up according to the type of changes desired (main layer, stripe, skinů).

Accordingly combinations of two and up to five extruders are used together with one or both of the

following changing valve systems.

Principle

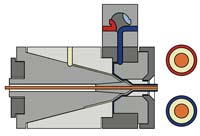

UNITEK offers the patented UCCS valve as well as the ULCS valve which is working according to

the layer change principle.

- Change color at full line speed

- An axial movement of the piston brings both extruders into feeding position

- Particularly suitable for thin wall products and short production runs

- Run continuously without needing to set-up again

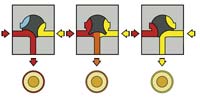

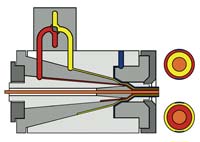

UCCS: Color Change System

- Change over between the two extruders is made by turning the piston

- One extruder is in working position the other one is in bleeding position (stand-by)

- In the extruder currently in bleeding position the color is changed to the next one to be produced

- The piston has 1 working and 2 bleeding channels. The material flows left/right (red) or right/left (yellow) into the head and never stands still inside the working channels

- During change over the material flow is not interrupted (see middle position)

|

|

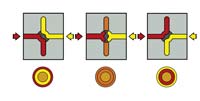

ULCS: Layer Changing System

- Depending on the position of the valve, the mass from one extruder is diverted to the inside (buried/hidden) whereas the other is diverted to the outside (desired color)

- During switch over the material flow is not interrupted (see middle illustration)

- Color changes are made in the (non visible) layer

- No extreme short production runs (time required for changing color in the inner layer determines minimum run length)

|

|